CHS EPOXY 474 and TELALIT 0492 – Penetration for Concrete

Code: 8008/15K 8008/61- Choose variantProduct detailed description

DESCRIPTION

Epoxy resin CHS-EPOXY 474 (component A) with the corresponding hardener TELALIT 0492 (component B) is designed for use in low-viscosity epoxy system for normal or elevated temperature processing.

USAGE

Penetrating coating for concrete (for concrete with a moisture content of up to 10 %), also as a fine leveling material for concrete substrates. Forms an adhesive bridge for top coating epoxy systems, cast epoxy floor coverings, for stone carpets, etc.

- Highway, roads,

- Bridges constructions,

- Parking, ramps and other extremely loaded surface.

PROPERTIES

- Chemical base: 2-K epoxide,

- Mixing ratio: 100 : 23 by weight,

- Application temperature: Ideally 10-30 °C,

- Application technique: Roller,

- Workability time: 20 min. at 20 °C, 10 min. at 30 °C,

- Material consumption: 0.2-0.7 kg/m2 for one coat (depending on the quality of the substrate and its porosity; apply 1-2 coats),

- Drying: walkable after 24 hours.

ADVANTAGES

- Simple application,

- Solvent free, less odor,

- Excellent adhesion to substrate,

- Application to early age (fresh) concrete,

- Low viscosity system,

- High penetration ability,

- Thermal resistance with bitumen/asphalt strips,

- Excellent resistance to water and chemicals.

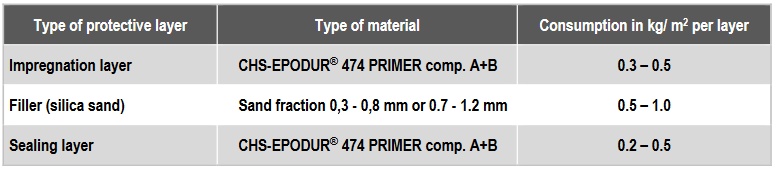

CONSUMPTION

PREPARATION AND PROPERTIES OF CONCRETE SUBSTRATE

- The concrete substrate must be dry, free of cracks, and excessive roughness. It must not be curled or dusted with cement.

- The surface of the concrete must have a rough, non-smooth macro-texture, therefore, the concrete trowel should not be used on the surfaces without additional treatment.

- The substrate must be protected from the effects of pressurized water. If the surface of the substrate is damaged (loose materials, corrosion, raised cement milk, etc.) or contaminated with oil, grease, asphalt, etc., mechanical preparation such as grinding, captive shoot blasting with sand or steel balls, or other verified and appropriate method should be used to degrease substrate surface and produce suitable profile for the application of a resin. The characteristics of the concrete substrate are given in the table below.

- Reparation of cracks of width up to 0.2 mm is performed using a penetration (so-called anchoring impregnation) coating.

- Reparation of cracks and surface roughness over 0.2 mm or more is performed by using CHS-EPODUR® 474 PRIMER with silica sand filler (a combination of fractions from 1/3 of 0.1 to 0.3 mm and from 2/3 of 0.7 to 1.2 mm) in a ratio of 1: 6.

- In case of fresh concrete application, no peeling may occur in an area larger than 1 mm2. It must not contain incoherent parts, cracks or other disturbances. The tensile strength must be at least 1.5 N/mm2, with a minimum of 75 % fracture in concrete.

- The substrate temperature must be at least 3 °C above the dew point.

- Required parameters of the concrete substrate

- Compressive strength for loaded surfaces min. 21.5 N/mm2,

- Compressive strength for walkable surfaces min. 14.7 N/mm2,

- Adhesion min. 1.5 N/mm2.

APPLICATION CONDITIONS

- Minimum air and substrate temperature: +10 °C/+10 °C,

- Maximum air and substrate temperature: +30 °C/+30 °C,

- Maximum air humidity: 85 %,

- The substrate temperature must be at least 3 °C above the dew point,

- Resin and hardener must be stored at temperatures 15-25 °C at least 1 day before application.

APPLICATION

Mixing ratio of CHS-EPODUR® 474 PRIMER: Component A 100 wt. parts + Component B 23 wt. parts

Mixing

- Mix up component A and component B in the right mixing ratio to obtain completely homogenous consistency. Do not prepare more material than can be comfortably applied within the pot life. For pot life see table below.

- The mixture of component A and component B must be poured into a clean container and mixed for a 1 minute before application.

- The mixture must be processed as soon as possible. At temperatures above 25 °C, the pot life of the mixed system is significantly reduced.

APPLICATION PROCEDURE

Impregnation layer

- The penetration mixture is applied on the treated and cleaned substrate with a suitable roller in an amount of 0.3-0.5 kg/m2 depending on the absorbency of the substrate until full saturation.

- The dry silica sand with a 0.3-0.8 mm or 0.7-1.2 mm fraction is applied uniformly on the fresh, non-dried layer to provide a bond bridge for the subsequent layer.

- Incoherent parts must be sweep away from the surface.

Sealing layer

- On the cured and swept substrate, a second layer is applied in an amount up to 0.5 kg / m2 with a suitable roller. Note: protect the fresh layer from direct contact with water and condensation for 24 hours after application.

Pot life

- Temperature 12 °C: 50 min; 20 °C: 25 min; 30 °C: 10 min.

Cleaning of tools

- All tools and equipment must be cleaned immediately after use with organic solvent based on acetone. Cured material can be removed mechanically from tools.

- Wash soiled hands and skin thoroughly in hot soapy water.

HANDLING PRECAUTIONS

- Avoid contact with the skin, eyes and avoid breathing its vapor.

- Wear protective gloves when mixing or using.

- If in eyes, hold eyes open, flood with water for at least 15 minutes and see a doctor, if skin contact occurs, remove contaminated clothing and wash skin thoroughly.

Additional parameters

| Category: | EPOXY RESINS |

|---|---|

| Warranty: | 1 year |

| Certifikace styku s potravinami: | Ne |

| UV stabilita: | Střední |

| DLE TYPU PRYSKYŘICE: | PENETRACE, PODLAHY |

| TYP VÝROBKU: | NÁTĚR NA PODLAHU, PENETRACE NA BETON |

| Míchací poměr: | 100:23hm% |

| Doba zpracovatelnosti: | 30 min(10°C), 20 min(20°C), 10 min(30°C) |

| Doba vytvrzení (pochozí): | 36 h(10°C), 24 h(20°C), 12 h(30°C). |

| Doba vytvrzení (úplná): | 9 dní(10°C), 7 dní(20°C), 6 dní(30°C) |

| Spotřeba při aplikaci penetrace: | 0,3-0,5kg/m2 |

| Spotřeba při aplikace vyrovnávací stěrka: | 0,6-1,2kg/m2 |

| Spotřeba při aplikaci polymermalta: | 0,4-0,5kg/m2/1mm vrstvy |

| Spotřeba při aplikaci polymerbeton: | 2,6 kg/m2/1cm vrstvy |

| Balení: | 15kg; 61,5kg |

Be the first who will post an article to this item!