Calculation of epoxy resin consumption

How much resin is needed for your project? By subtracting the volume of the wood from the volume of the mold:

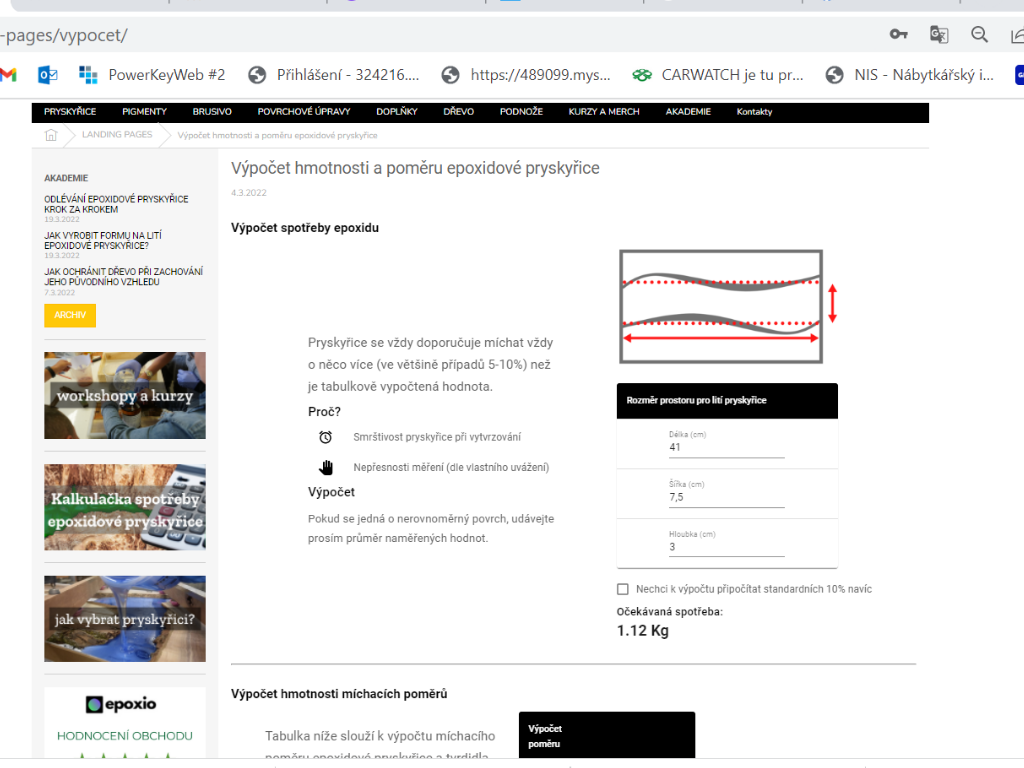

Calculation of the internal volume of the mold

Internal mold volume Vf = length (m) x width (m) x depth (mm). The resulting volume is in (L).

Calculation of the volume of wood

Wood volume: Vd = length (m) x width (m) x thickness (mm). From this volume of wood, subtract the approximate volume of cavities and gaps in the wood (in liters).

Calculation of resin volume

VP = Vf - Vd (in liters) and you get a very good estimate of the resin volume needed.

This way we get the volume in liters and the resin is sold in kg because it has to be weighed. It is converted to weight via density. The density of VEROPAL systems (except Veropal ART 430) is very close to the density of water (their density is between 1.05-1.13 kg/dm3), so when we want to estimate very roughly the need of material, we can calculate that the mass of the mixture is approximately equal to the volume mixtures. If the shapes for casting are complicated and complex, we recommend either dividing the area into simpler parts and then calculating the volume for them, or using, for example, very fine sand and filling the area that we want to pour epoxy with this sand. The obtained volume of sand is then multiplied by a coefficient of 1.15 (elimination of air between grains of sand) and we get the approximate volume that we will pour.

We always mix a little more resin than we calculate, mainly due to shrinkage of the resin during curing, underflow of the wood, wrapping around the wood in the mold, partial absorption of the resin into the wood, plus the need for resin to test the pigment or shade of the resin. We recommend an addition of approximately + 5 to 10 % to the calculated volume.

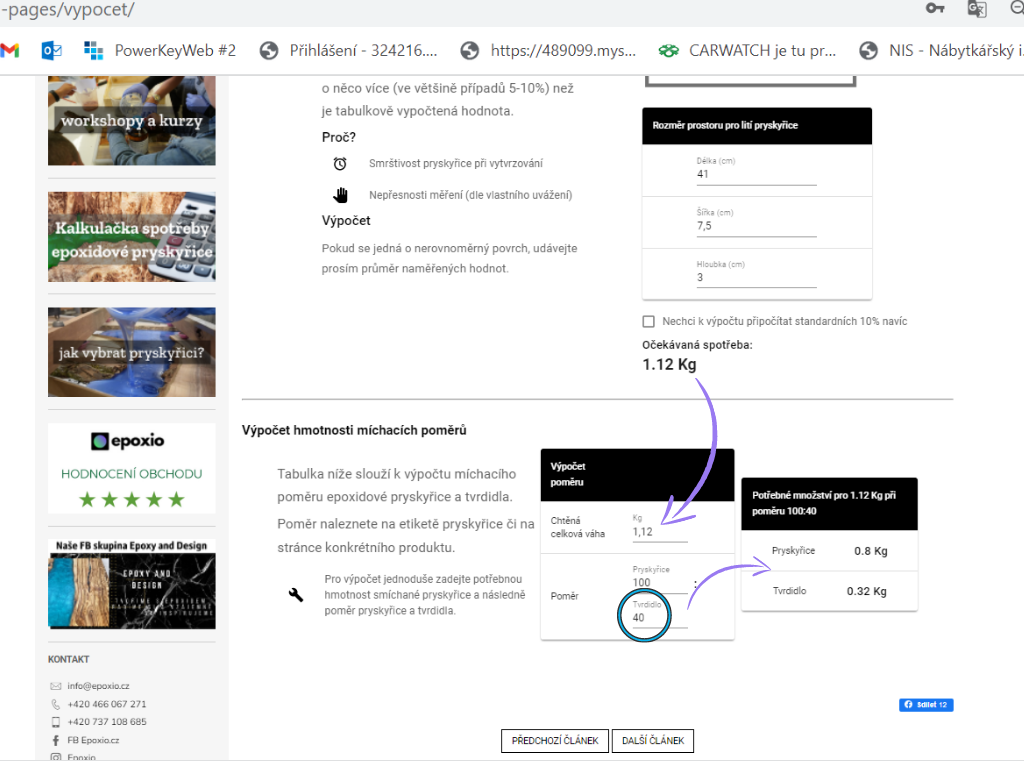

We made an epoxy resin consumption calculator for our customers and for ourselves. It consists of 2 tables. In the table above, the extrapolated dimensions must be entered and the amount of epoxy system needed for the given project will be calculated immediately. This final number already contains 10 % extra (wood wrapping, wood underflow, partial absorption into the wood, shrinkage during curing, etc.). In case you don't want the extra 10 %, you can eliminate it by checking it. We then insert the resulting number from the first table into the second table, and at the same time enter the correct mixing ratio according to the epoxy system we are using. We immediately get the result of how much to boil component A and how much to weigh component B.