Your epoxy table after a successful casting will require some care to keep it looking its best. It will need to be protected against certain influences that can damage it. These include direct sunlight, UV radiation, high temperature in the form of hot objects and scratching with sharp objects.

UV radiation, direct sun

Although the epoxies used (especially those with maximum resistance to UV radiation) are characterized by excellent resistance to the effects of UV radiation in the long term, these products are intended for interior use. To prolong the appearance of the product, it is recommended to place them out of direct sunlight. Possible degradation of the epoxy due to UV radiation is manifested by the yellowing of the epoxy or a change in the color shade in the case of dyeing with pigments. The UV resistance and lifetime of the casting can be significantly extended by painting it with LV CC 250 clear coat, which contains silicon nanoparticles (increases scratch resistance by 30 %) and, thanks to a relatively high concentration of UV-blocking substances, significantly slows down the effect of UV radiation.

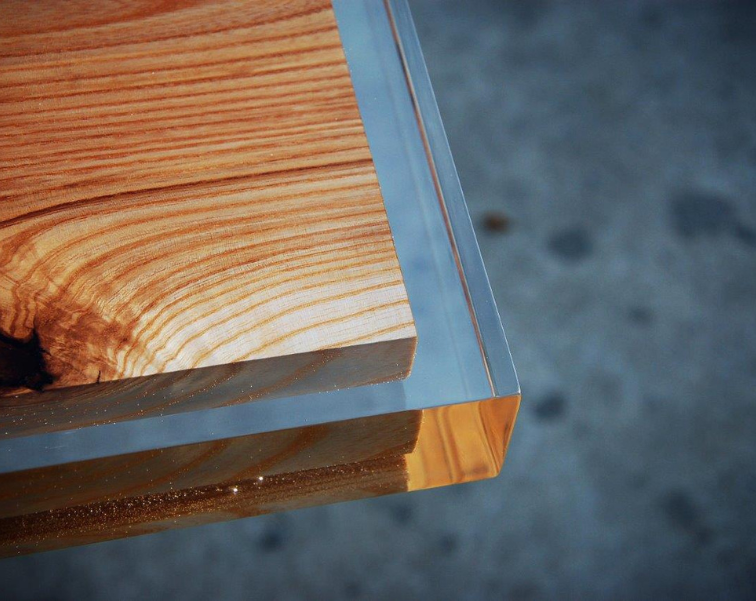

Detail of a travertine and Veropal UV PLUS 100 table

Detail of a travertine and Veropal UV PLUS 100 table Horké předměty

High temperature or hot objects can deform the table or damage its appearance. The table should not be placed directly near a heat source (e.g. fireplace...). The most common damage to the resin occurs at the point of contact with a hot object (change in color, extruded wheel, after coffee cups or hot pots, etc.). Therefore, the epoxy surface must be best protected by placing potentially hot objects on heat-resistant mats (saucers, place mats, etc.) to insulate the surface from direct heat from the hot object.

Scratching

Sliding sharp objects or hard ceramic cups directly over the epoxy surface can cause scratches on it, which are especially visible against the light. This wear and tear can be avoided by using place mats and blankets, or by not moving these items around the table. In the event that a scratch occurs due to contact with a sharp object, this scratch can always be repaired locally by re-coating the area with resin and re-polishing the damaged area to its original appearance. Re-sanding and re-polishing is also chosen in the event that micro-scratches from normal wear during use have already taken the original shine from the table (See a special article about polishing).

Table made of olive and epoxy resin Veropal UV PLUS 100

Table made of olive and epoxy resin Veropal UV PLUS 100 Maintenance of the table

It is best to clean the table with a cotton seamless cloth or microfiber and use the recommended suitable, non-aggressive and gentle cleaning agents (e.g. Rubio Surface Care or Rubio Refresh Eco). Agents containing abrasives, ammonia, solvents and colored cleaners can damage the surface finish of the table and thus spoil its overall appearance. If you want to revitalize the surface of the table, especially the wood, Rubio Maintenance Oil can be used.