Epoxy Resins

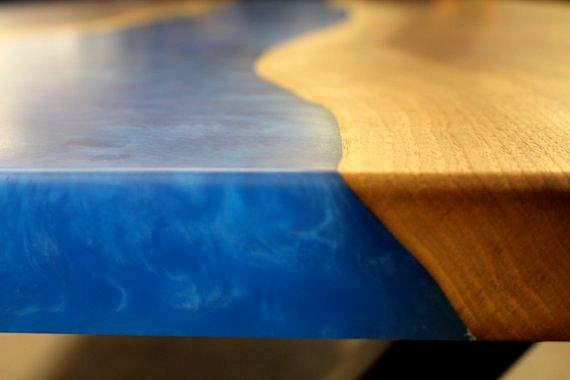

Epoxy resins are mostly two-component liquids that, after mixing the components, begin to polymerize and produce a hard, chemically resistant and dimensionally stable casting. These resins are used in the production of designer furniture, especially river tables made of epoxy resin, conference and side tables, clocks made of resin, jewelry made of resin, as well as epoxy serving boards, epoxy lamps, epoxy paintings and other decorative products. All epoxy resins can be colored with compatible pigments and dyes depending on the desired effects.

The choice of resin depends on several factors:

- The purpose of using epoxy,

- Resin properties and parameters,

- Size and type of casting,

- Price.

Epoxy resins according to use

According to use, epoxy casting resins are divided into:

- Casting (casting) resins – Clear, low-viscosity epoxies for epoxy production, casting of epoxy tables, doors, headboards, clocks, lamps, jewelry, serving boards, etc.) – VEROPAL UV PLUS 121, VEROPAL UV PLUS 100, VEROPAL UV PLUS 130, VEROPAL CLEARCAST 300, VEROPAL REBIDO 500.

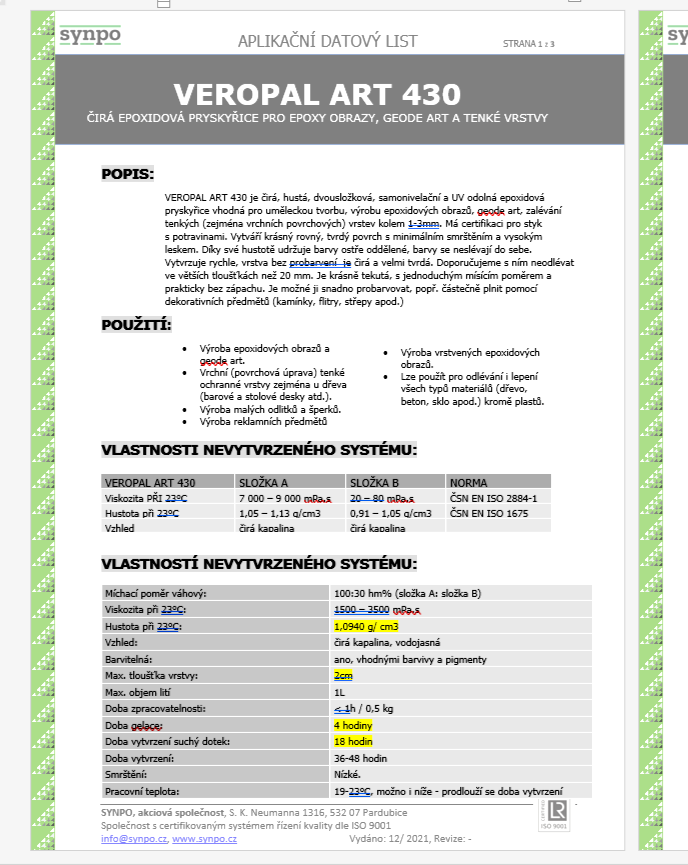

- Special (effect) resins – Developed for special purposes (e.g. for paintings and geode art (VEROPAL ART 430), for the technique of repeated casting in thin layers (VEROPAL REBIDO 500), high-strength for repairs of deformed wood VEROPAL FIXWOOD, quick for quick repairs in product processing, VEROPAL QUICK, VEROPAL REBIDO 500, VEROPAL FIXWOOD, etc.).

- Penetrating resin – For sealing porous materials (wood) and thereby eliminating bubbles during the hardening of the casting resin and for creating an adhesive bridge for subsequent layers (VEROPAL PEN 10, VEROPAL WSB E-LV, VEROPAL UV PLUS 121).

- Resin for surface layers (coating, table top resin) - for casting the top layer or pouring over wooden surfaces and their preservation (tables, coffee tables, clocks, etc.) – VEROPAL UV PLUS 121, VEROPAL TOPCOAT 600, VEROPAL ART 430, VEROPAL REBIDO 500.

- Stabilizing resin – For strengthening and stabilizing rotten or unstrengthened parts of wood, and for the production of stabilized wood for luxury products (knife handles, jewelry, golf club handles, gear levers of luxury cars, luxury writing pens, etc.) – VEROPAL WSB E-LV, VEROPAL WSB A.

- Floor resins – Casting resins for designer cast floors and for 3D clear floors – VEROPAL 3D FLOOR.

- Laminating resins – Epoxy two-component systems with lower viscosity intended for lamination of composite materials, either by manual lamination, winding, RTM/RIM/SCRIMP or infusion – VEROPAL LAM 30, VEROPAL LAM 80, VEROPAL LAM 200, VEROPAL LAM 400, VEROPAL LAM 1000.

Important parameters of epoxies – Explanation

Each epoxy resin has its own defined properties and one should know always before casting (look in the technical sheet) what parameters and properties the given resin has and whether it is suitable for the given project. This should play an important role in deciding the type of resin. Among the most important parameters to monitor and which depend on the use of the resin are:

- Food contact certification – Important if you produce tables, tables, bowls, etc., i.e. products that come into contact with food.

- UV resistance – Defines the resistance of the resin against UV radiation. UV radiation causes degradation = yellowing of any epoxy and this parameter tells us how long and to what shade the resin will change shade. There are epoxies on the market that turn yellow to a deep yellow color in a few months to epoxies that change their color to a very subtle yellowish shade in 5-6 years.

- Gelation time – Gefines the time during which the resin polymerizes enough to increase its density to the consistency of honey. Most of the pigment effects are formed at this time.

- Mixing ratio – It is the calculated ratio of resin (component A) and hardener (component B), which must be followed as accurate as possible, so that the resin has the right properties.

- Workability time – The time during which the resin can be comfortably worked with.

- Full curing time – The time after which the resin is already cured, the epoxy is fully polymerized and is ready for processing by sanding, milling, polishing, drilling, turning, etc.

- Hardness in ShA (Shore A) units – Determines how hard or tough the material is after curing. The ideal value is between 75-80 ShA. Systems that are too hard are then more fragile and at the same time are not able to absorb the internal stress caused by woodworking.

- Maximum casting layer – What maximum layer can be cast at one time without risking an exothermic reaction ("resin boiling").

- Maximum casting volume – What is the maximum volume of resin that can be mixed and cast at once without risking an exothermic reaction of the resin.

- Glass transition temperature – Determines the temperature resistance of epoxy. This is the temperature at which the polymer changes from a hard glassy state to a flexible rubbery state. The process is reversible, i.e. when the temperature is lowered, the polymer hardens again.

- Epoxy shrinkage – Defines the loss of epoxy volume during curing. Its manifestation is a drop in the cast level during hardening and micro ripples on the surface of the hardened casting.

- Epoxy viscosity in mPa.s – Shows how fluid the resin is. Casting resins tend to have a lower viscosity, while resins for various effects have a higher viscosity.

Epoxy resins according to size and type of casting

Therefore, depending on the size and type of casting, the types of resin differ and are divided into:

- Casting resin for small castings such as jewelry, writing pens, small decorations, coasters, etc. This type of resin have low viscosity, quick hardening (on the order of hours to max. 1 day), are clear, harder and more fragile. These include VEROPAL UV PLUS 121, VEROPAL REBIDO 500, VEROPAL ART 430.

- Casting resin for medium castings such as epoxy serving boards, small pieces of furniture, epoxy lamps, epoxy clocks, medium coffee tables made of epoxy resin and wood, etc. This type of resin have lower viscosity, slower curing (2-3 days), layers up to e.g. 5 cm can be cast, they are clear and hard. This group is represented by VEROPAL CLEARCAST 300, VEROPAL UV PLUS 130, VEROPAL TRANSPARENT 200.

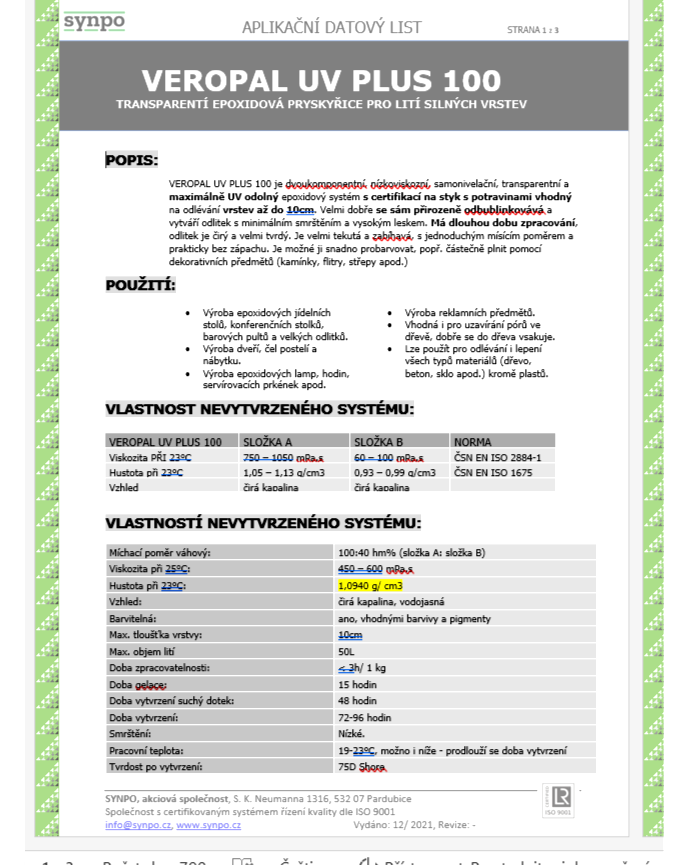

- Casting resins for large castings such as dining tables made of resin and wood, so-called river tables, coffee tables, doors, headboards, epoxy vases, larger pieces of furniture, etc. These epoxy resins have low viscosity, slow hardening (3-5 days), tehy are usable larger volumes (up to e.g. 50 L) and thicker layers (e.g. 10-12 cm). The representative of this group is VEROPAL UV PLUS 100.

- Casting resin on thin layers (table top resin) to create a "glassy" surface of a cast from wood and resin. This type of clear resin have low viscosity, relatively fast curing, good flow, minimal shrinkage and good surface resistance. These include VEROPAL TOPCOAT 600, VEROPAL REBIDO 500, VEROPAL ART 430, VEROPAL UV PLUS 121.

- Artistic casting resins for creating epoxy paintings, geode art, various effects, etc. Resins of this type have high viscosity, relatively fast curing, are clear, with minimal shrinkage. This includes VEROPAL ART 430, VEROPAL REBIDO 500.

Epoxy resins and price

The quality and performance or parameters of epoxy casting resin go hand in hand with its price. You get what you pay for. There are many types and brands of epoxies on the market, from cheap resins with a distinctly poor performance (yellowing to orange in a few months, rapid degradation of the epoxy, poor debubbling, poor machinability...) to more expensive epoxies with excellent performance (only a very slight yellowish tint up to 5 years, great clarity and debubbling, etc.). It is also necessary to approach the choice wisely and filter out marketing slogans such as "ultra-diamond crystal clear resin with a price far below the average" – often the poor performance of the resin is hidden behind this. If you want to make a casting with a long life, so that it does not change or degrade over time, be sure to choose a proven product with the best possible price/performance ratio. Veropal resin from the Czech manufacturer Synpo consistently meets this parameter.