EPODUR STONE UV – Epoxy Resin for Stone Carpet

Code: 7996Product detailed description

Description: Two-component low-viscosity UV-stable epoxy resin.

Use: Special system for the preparation of stone carpets used as a final treatment in exteriors and interiors, for the restoration of damaged concrete, to extend life of concrete structures showing signs of degradation,

- Chemical base: 2-K epoxide,

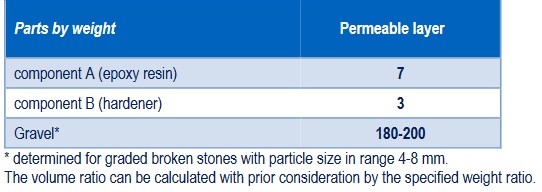

- Mixing ratio: 100 : 43 by weight,

- Addition of filler: 18-20 kg of aggregate per 1 kg of mixture,

- Recommended thickness: 20-40 µm,

- Application temperature: Ideally 10-30 °C,

- Application technique: Masonry tools,

- Workability time: 30 min. at 23 °C; 50 min. at 23°C in mix with filler,

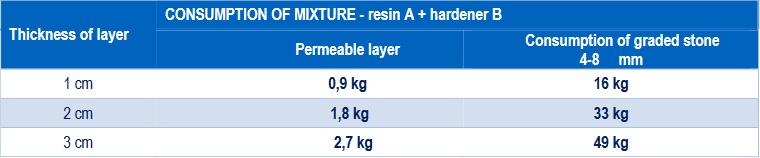

- Material consumption: 0.9 kg of binder and 16 kg of filler (1cm layer of carpet); 1.8 kg of binder and 33 kg of filler (2cm layer of carpet),

- Drying: Walkable after 24 hours. Full load depending on ambient temperature in 3-10 days.

CONSUMPTION

Consumption of material depends on a thickness of stone layer and also on a size of pebbles.

Estimated consumption per 1 m2 incl. graded broken stone:

CHS-EPODUR STONE UV is two component low viscous system. Component A is epoxy resin. Component B is special amine

hardener.

Consumption of the material depends on the properties of the underlying surface and the size of the stones. It is recommended

to apply a layer of about 1.5 cm using aggregate of particle size 4-8 mm. Using a different size aggregates may negatively

affect the strength of the surface. For more information, contact our technical service.

PREPARATION AND PROPERTIES OF SUBSTRATE

Concrete surface

- Must be solid, clean and free of cracks, may not be insulated against ground moisture. Concrete mustn’t be absolutely smooth and powdered by cement.

- If the substrate surface is damaged (spalling, corrosion or cement milk occurs on the surface), or contaminated by diesel, oil, asphalt, then grinding, sandblasting, shot blasting or high pressure water blasting must be done.

- In a case of lower quality substrate, penetration by mixture of CHS-EPOXY 474 /TELALIT 0492 or EPOSTYL 200 V is recommended to be carried out.

- It is necessary to take into consideration the expansion joints.

Gravel base

- Must be compacted, free from impurities such as oil, dirt, leaves, moss, etc.

- Penetration must not be done.

- In case of doubt about the strength of the surface contact Technical Service.

Tiles

- The surface must be dry, clean and consistent.

- If the substrate surface is damaged (spalling, corrosion) or contaminated by diesel, oil, asphalt, then grinding, sandblasting, shot blasting or high pressure water blasting must be done.

- It is recommended to remove the glaze by grinding.

- It is necessary to penetrate the surface by the mixture of CHS-EPOXY 474 with TELALIT 0492 after grinding.

APPLICATION CONDITIONS

- The minimum allowed temperature of the surrounding environment and the substrate is 10 °C. The application is recommended to be carried out in dry weather.

- Temperature of the resin and hardener before application should be in the range of 15-25 °C.

- Gravel must be clean. Contaminants significantly affect not only the final look, but also cohesion and mechanical properties of the stone carpets. It is suitable to rinse the gravel and leave it to drain properly. When CHS-EPODUR STONE UV is used on vertical surfaces, suitable formwork must be used. To prevent sticking of the stones to formwork, it is necessary to use a suitable separator (wax, oil, etc.). The use of plastic foils is not recommended for this purpose due to the possible appearance of surface defects after removal.

PROCESSING PROCEDURE

The mixing ratio of resin, hardener and gravel:

Mixing

Firstly, it is necessary to mix thoroughly the resin and hardener by suitable mixer for 2-3 minutes. The resulting mixture of resin and hardener must be thoroughly mixed with the gravel by concrete mixer or hand tools for about 5 minutes.

Procedures

After spreading the material over the surface, the levelling by building trowels is carried out. In case of application onto large areas the material is levelled by straight batten. It is necessary to take into consideration the expansion joints.

Pot life

- 50 minutes at 23 °C in total.

- The mixture of CHS-EPODUR STONE UV component A + B can be processed in about 30 minutes at 23 °C.

- The pot life becomes shorter at temperatures above 23° C.

- Always prepare such amount of compound that can be applied during the above-mentioned period.

Tools and cleaning

- Tools, mixers and all equipment must be immediately cleaned by solvent based on a mixture of xylene and butanol or acetone, for example, S 6003, 6005, 6023, 6028, 6812. Cured solid material can be removed only mechanically.

CURING CONDITIONS

Stone carpet is walkable after 24 hours if application temperature is above 15 °C. Cured surface is fully loaded after 3-5 days, if the temperature drops below 15 °C. At lower temperatures, the time are doubles.

STORAGE AND SHELF LIFE

Product should be kept in original closed packaging in dry storehouses at temperature 5-25 °C separately from hardeners and sources of ignition. Shelf-life is 12 months since the date of production.

SAFETY INSTRUCTIONS

Consistent use of protective equipment, protect your skin and eyes from contact with liquid epoxy resins and hardeners. Wear suitable protective clothing (long sleeves and pants) and closed shoes. Always wear rubber gloves and glasses (or shield) during mixing and application of materials. Use suitable respirator, when dusty processes are carried out (grinding). Consistent ventilation prevents inhalation of fumes. In case of contact with eyes, rinse as quickly as possible with water, continue it as long as possible but at least 20 minutes, and secure medical attention immediately. In case of contact with skin, remove contaminated clothing and flush the most

intensely affected area with clean, warm (30-32 °C) water. Move the person to a doctor. For more information, see the Safety Data Sheet.

Additional parameters

| Category: | STONE CARPET |

|---|---|

| Warranty: | 1 year |

| Weight: | 16 kg |

| Certifikace styku s potravinami: | Ne |

| UV stabilita: | Střední |

| DLE TYPU PRYSKYŘICE: | PODLAHY, KAMENNÝ KOBEREC |

| TYP VÝROBKU: | KAMENNÝ KOBEREC |

Be the first who will post an article to this item!